The dry-wet combined air cooling tower is a closed cooling device that has both dry-cooling "water-saving" characteristics and wet-cooling "high-efficiency" characteristics. It mainly uses dry-air cooling to achieve water saving. When the ambient temperature is high, it is supplemented by Partial wet cooling, with a small amount of water consumption to achieve lower cooling water temperature requirements. The dry-wet combined air cooling tower takes a critical water spray temperature point as the design boundary condition, organically combines dry air cooling and wet air cooling, and separately calculates and calculates the equipment investment, floor space, and water consumption of dry and wet cooling to achieve water saving. The optimized combination with investment has been widely used in industrial production in water-scarce areas such as Northwest China and North China.

Product details

Application field

Dry and wet combined air cooling towers are widely used in power, coal chemical industry, metallurgy and other industries, such as: power plant auxiliary equipment circulating cooling water system, large machine air cooling auxiliary peak cooling system, flue gas water extraction circulating cooling system, coal chemical coking production process cycle Cooling water system, methanol, coal-based ethanol and other closed industrial circulating cooling water systems; ironworks blast furnace, hot air furnace circulating cooling water system, other heating furnaces, melting furnaces, diathermy furnaces and other industrial furnaces and circulating cooling water systems, etc. Wait.

Working principle

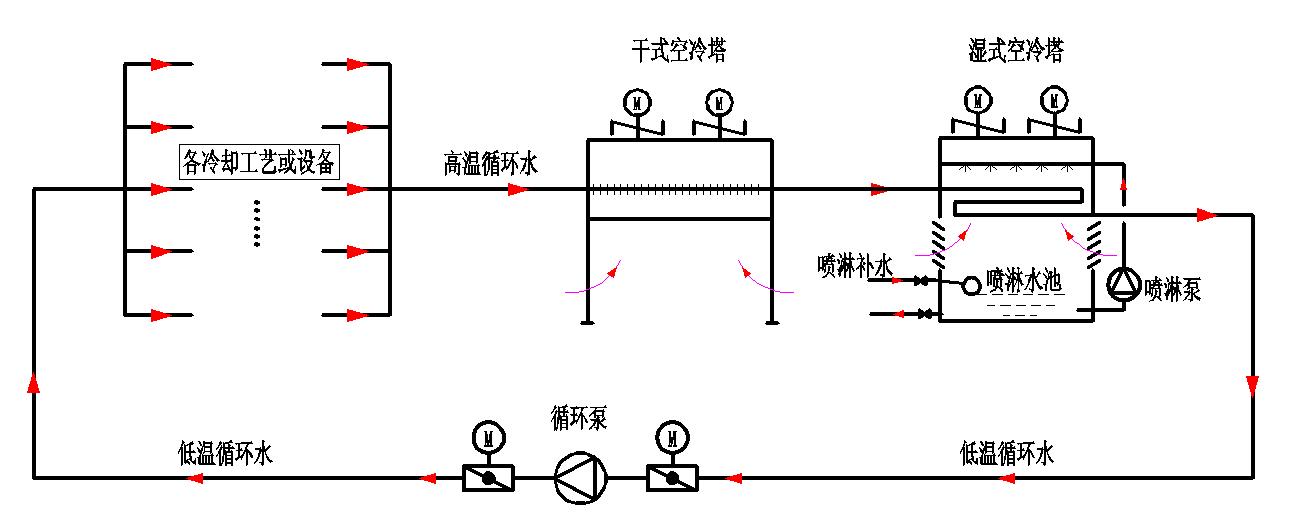

The high-temperature circulating water first enters the dry and cold section, the circulating water is taken inside the pipe, the outside of the pipe is forcedly ventilated to cool down, and aluminum fins are used to enhance heat transfer. After cooling in the dry and cold section, the circulating water enters the wet and cold section to continue cooling. The wet and cold section is equipped with a spray system, including a spray pump, a spray tank, and a spray water distribution device. Forced ventilation, supplemented by spray water at the same time, spray water exchanges heat with the circulating water in the tube through the heat exchange element, and takes away the heat by the latent heat of evaporation and the sensible heat exchange with the air to achieve temperature reduction, reaching the temperature required by the process, To cool each process or equipment.